Unknown Facts About Infill Panels For Windows

Fixings need exterior gain access to. Aluminum frameworks are naturally corrosion resistant in lots of environments if anodized and also effectively sealed or painted with baked-on fluoropolymer paint. Light weight aluminum structures go through wear and tear of the finishing as well as corrosion of aluminum in severe (industrial, seaside) atmospheres and galvanic deterioration from call with different steels.

Drape walls and border sealants call for upkeep to take full advantage of the life span of the drape walls. Border sealants, properly developed as well as installed, have a regular solution life of 10 to 15 years although breaches are likely from day one. Removal as well as substitute of perimeter sealants requires precise surface area prep work and also proper describing.

About Infill Panel

Recover as well as demolition professionals generally require a minimum of 1,000 sq feet or even more of window/curtain wall surface to make product recycling cost-effective (smaller quantities are generally disposed as basic trash). Recycling is less economical if the aluminum is infected with sealants, broken glazing, etc., as salvage companies pay considerably much less for the product.

Select a drape wall with a shown record in similar applications as well as direct exposures. Verifying record may call for considerable research by the developer. ASTM E1825 gives advice. decorative infill panels. Testimonial laboratory examination results of systems or comparable custom-made systems for air, water, as well as structural resistance, warmth transmission, condensation resistance, sound transmission, as well as operability.

Curtain wall style must start with the assumption that exterior glazing seals, boundary sealer joints and also curtain wall surface sills will certainly leakage. The complying with summarizes recommended features: Select structures with wept glazing and pocket sills sloped to the exterior to gather water that passes through the glazing and drain it to the outside.

Each polishing pocket needs to be completely separated from adjacent glazing pockets. Supply a sill blinking with end dams as well as with an upturned back leg showed up right into the glazing pocket at the base of the drape wall to collect and drain drape wall sill leak; give jamb flashings to route border leak down to the sill flashing.

Use as numerous 1/4-inch by 2-inch slots as needed for pressure-equalized systems. Design the water drainage system to take care of condensation in addition to rain. Drape wall surface borders must have flashings important site (sill, jambs as well as head) that are secured to the air and also water barrier at nearby walls. Incline head and sill flashings to the outside to advertise water drainage.

The smart Trick of Mapes Architectural Panels That Nobody is Talking About

Drape wall surface ought to have a key air/water seal between the shoulder of the tube at the plane of the glazing pocket and also the air barrier of the adjacent construction. Border sealants work as a rainscreen for restricting air and also water penetration via the outer aircraft of the wall, but must not be relied upon as the sole air/water infiltration obstacle.

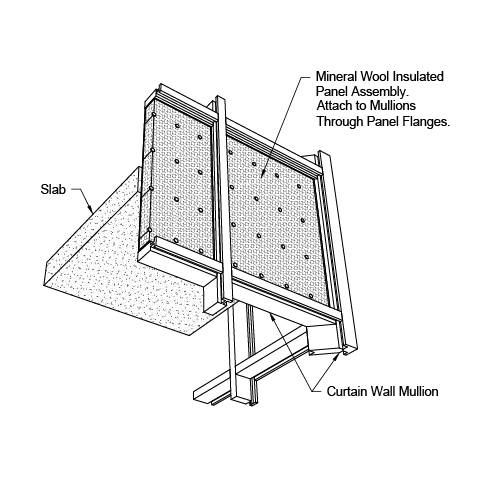

Stress Plate Glazing: In this system the glass as well as infill panels are set up from the exterior, commonly against completely dry gaskets. The external layer of gaskets is installed as well as the gaskets are pressed versus the glass by the torque related to bolts securing a constant pressure plate. The plate is later on generally covered with a snap-on mullion cover - curtain wall metal panel infill.

The framework is dealt with as well as exterior completely dry gaskets are set up. Usually just the leading interior mullion has a removable quit. The glass device is slid into a deep glazing pocket on one jamb far sufficient to allow removing the opposite jamb and also is after that moved back into the opposite glazing pocket as well as after that dropped right into the sill glazing pocket.

Often this method is called "agitate" or "wiggle" glazing since of the adjustment necessary to get the glass right into place. Performance is slightly minimized because dry steel to steel joints occur at the ends of the detachable quit at a point that need to appropriately be air and watertight. Wet sealant heel beads will boost performance and also some systems consist of an additional gasket to form an air obstacle seal.

The Definitive Guide to Mapes Insulated Panels

Structural Silicone Glazing: In this system the glass or infill device is adhered to the frame with a bead of official site silicone. External silicone weather condition seals supplement the structural seal. Unitized systems are often architectural silicone glazed, particularly if four-side SSG is wanted. Two-sided SSG, with stress plate glazing or wiggle glazing on the other two sides is spandrel cam panel acceptable to be area installed.

True butt-glazing has no mullion or other back-up participant behind the joint as well as counts only on a sealant, usually silicone, in between the glass units to offer an excellent barrier seal. AAMA's Drape Wall Layout Overview offers assistance on window option for condensation resistance. Establish the required Condensation Resistance Aspect (CRF) based upon expected indoor moisture and also neighborhood climate data and choose a drape wall with a proper CRF.